Advanced 3D printing for heterogeneous and dynamic phantoms for dosimetry and imaging

Gabriel Paiva Fonseca,

The Netherlands

PO-1640

Abstract

Advanced 3D printing for heterogeneous and dynamic phantoms for dosimetry and imaging

Authors: Gabriel Paiva Fonseca1, Murillo Bellezzo2, Robert Voncken3, Behzad Rezaeifar4, Teun van Wagenberg4, Niklas Lackner4, Frank Verhaegen4

1Maastricht University, Radiotherapy, Maastricht, The Netherlands; 2Maastricht university, radiotherapy, Maastricht, The Netherlands; 3Maastro, radiotherapy, Maastricht, The Netherlands; 4Maastricht University, radiotherapy, Maastricht, The Netherlands

Show Affiliations

Hide Affiliations

Purpose or Objective

Technological

developments in 3D printing resulted in applications in several fields

including radiotherapy. It brings the opportunity to research and clinical

departments to develop new technologies and prototypes reaching the same level

of accuracy as commercial vendors. This report describes some of the

applications of 3D printing in our clinic and focuses on the 3D

printing technology rather than the detailed description of each application.

Material and Methods

Commercial and

in-house developed 3D printers were introduced in our research department early

in 2018 aiming to manufacture and test an in-house developed brachytherapy

applicator for rectal cancer and develop a new device for applicator

commissioning. This technology was then employed to develop custom 3D printed homogeneous

and heterogeneous phantoms based on patient anatomy for dosimetry and imaging and

also to develop prototypes of motion platforms currently being used in

combination with 3D printed phantoms for dosimetry. Although great geometrical

accuracy can be obtained, the material properties are often not well known. In

this study, more than 20 types of commercial materials (e.g., PC, PLA, ABS, PP,

Nylon, and TPU) were tested. In addition, a custom filament including ≈17% of Ca was developed to mimic bone.

Results

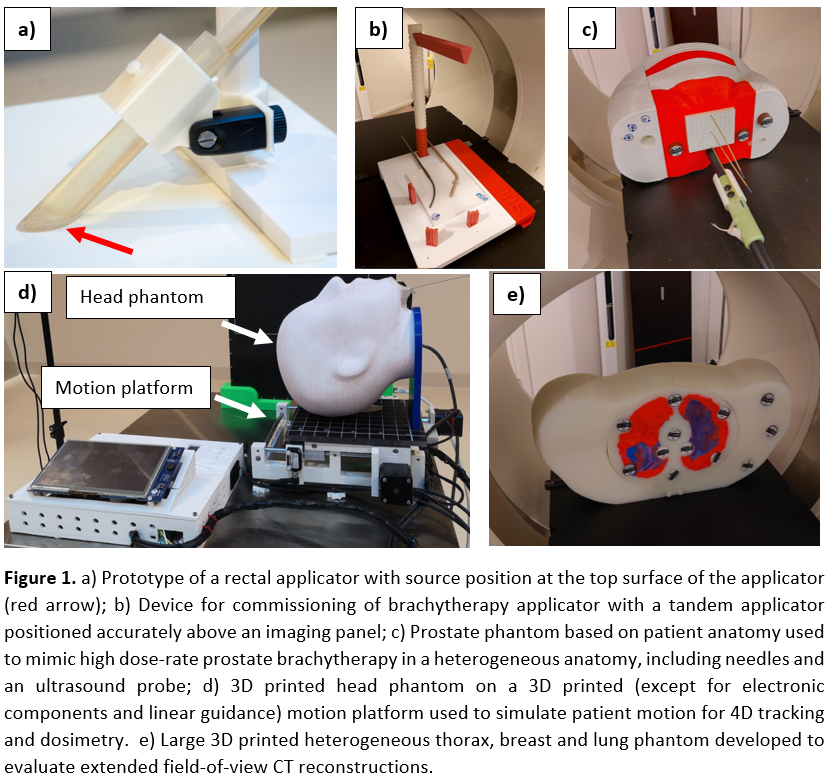

Fast prototyping

using 3D printing technologies was essential to quickly design and manufacture

applicators, phantoms and other devices with limited costs. The brachytherapy

applicator (Figure 1a) was eventually patented and further developed into a

commercial product by a major radiotherapy device vendor whilst the applicator

commissioning device (Figure 1b) is currently under clinical implementation.

Treatment verification methods are currently being developed using prostate

(Figure 1c) and head phantoms (Figure 1d) to perform static and dynamic

measurements using the 3D printed motion platform (Figure 1d). A phantom

(Figure 1e) based on the anatomy of a large patient (developed due to the lack

of commercial alternatives) was used to evaluate extended field-of-view CT

reconstruction. Tissue-equivalent materials for photon and proton therapy are

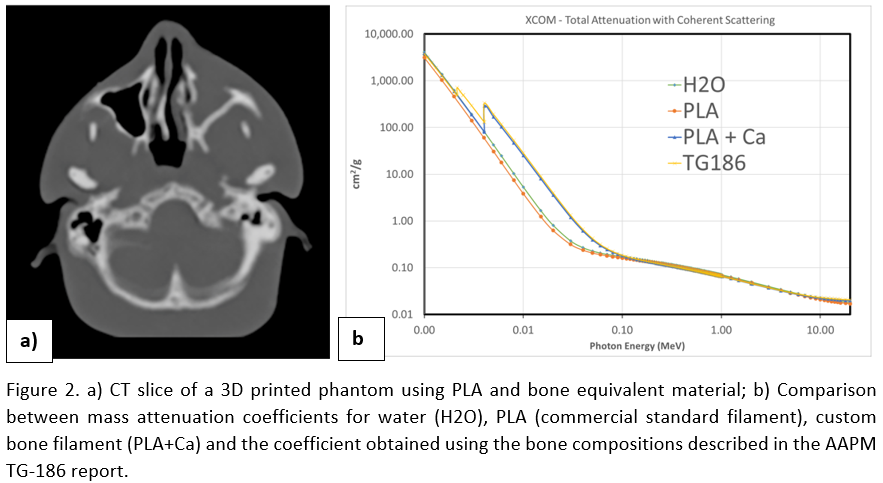

desirable for imaging and dosimetry with bone equivalent materials being the main

challenge. Our custom bone material (Figure 2a) showed similar behaviour as

commercial tissue-mimicking inserts regarding density, Hounsfield Units, and stopping

power ratios. In addition, mass attenuation coefficients are similar to ones

obtained using bone composition described in the literature.

Conclusion

3D printing

applications in radiotherapy or by specialized companies will continue to

increase providing an essential tool for affordable innovation and

customization (e.g. patient or application-specific phantoms). Nonetheless, in-house

developed prototypes need medical certification through regulations, risk

analysis, documentation and other requirements for implementation for which

hospitals may not be prepared.