A robotic dosimetry system by optical scanning of radiophotoluminescence coated immobilization masks

Laurence Delombaerde,

Belgium

PO-1711

Abstract

A robotic dosimetry system by optical scanning of radiophotoluminescence coated immobilization masks

Authors: Brent van der Heyden1, Marijke De Saint-Hubert1, Katleen Himschoot2, Rene Geelen2, Laurence Delombaerde3, Marco Caprioli4, Wouter Crijns3, Dirk Vandenbroucke2, Paul Leblans2, Luana de Freitas Nascimento1

1Belgian Nuclear Research Centre (SCK CEN), Research in Dosimetric Application group, Mol, Belgium; 2Agfa N.V., Corporate Innovation Office, Mortsel, Belgium; 3University Hospitals Leuven, Department of Radiation Oncology, Leuven, Belgium; 4KU Leuven, Department of Oncology, Leuven, Belgium

Show Affiliations

Hide Affiliations

Purpose or Objective

Thermoplastic fixation masks became standard immobilization technology in the fractionated radiation treatment of brain and head-and-neck cancer patients. This DoseMask project intends to transform masks into passive dosimeters by applying light-insensitive radiophotoluminescence (RPL) coatings before the thermoplastic shaping. A sub-mm thin RPL coating, covering the mask surface, would then store a measure of cumulated dose, which can be readout multiple times non-destructively by laser excitation. However, no configurable readout equipment exists today to measure the emitted RPL signal from complexly shaped mask surfaces. This work describes the development of a robotic readout system to measure RPL emission.

Material and Methods

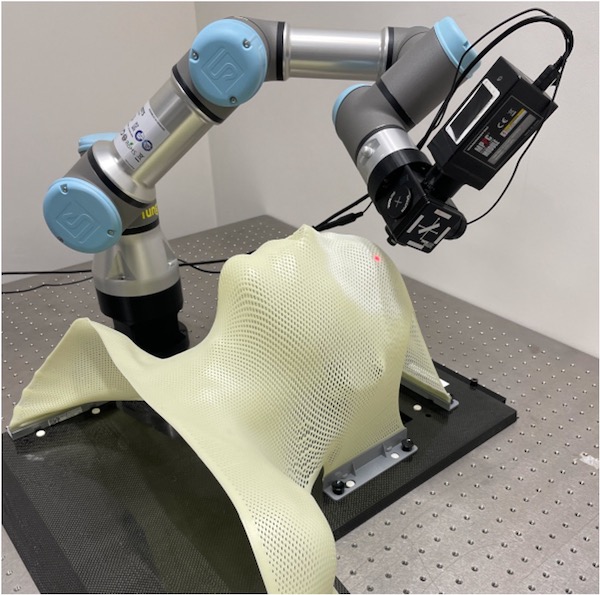

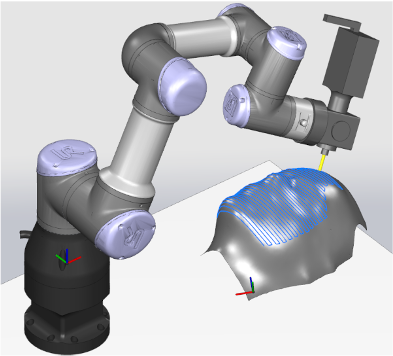

RPL sheets (5x5 cm2) were manufactured of Al2O3:C,Mg µm-powder mixed with a binder and deposited on a polyester substrate. Signal-to-noise measurements in a 2x2 cm2 central region-of-interest were performed on irradiated films (5 Gy) with a series of long- and short-pass optical filter combinations in the robotic optical head (Fig 1). A hand-held structured-light Artec Eva 3D scanner was used in HD-mode to digitize an old patient mask as a water-tight mesh model in Artec’s Studio software. The mesh was then loaded in an offline programming package for robots (Robotmaster V7.5) to plan the scanning trajectory of the optical head (incl. RPL detector, 635 nm excitation laser, 650 nm cut-on dichroic mirror, and filter set). Connection pieces were 3D printed in PLA. Scanning configurations and orientations were investigated to cover the fixation mask surface in discrete sub-mm steps.

Results

The highest signal-to-noise ratio between the RPL-scanned irradiated and non-irradiated films was found with a 700 nm long-pass and 825 nm short-pass filter combination, which were then included in the lens tube of the robotic optical head. A chalk coating had to be deposited on the fixation mask surface to improve digitization accuracy (±0.2 mm) and to avoid scanning artifacts due to white light reflectance. Mesh post-processing was required to align the 518 individual frames in scanning space, to fuse all frames into one single mesh object, to remove polygon outliers and mesh holes. This non-automated scanning and post-processing procedure currently requires ±30 minutes for one operator. A realistic simulation model was developed to generate a scanning protocol in sub-mm steps (Fig 2). Computer software was written in C# to communicate in 20 ms periods with the robot (3D+time) and the detector (RPL emission intensity).

Fig 1 The robot follows the mask curvature after digitization

Fig 2 Robot trajectory planning in Robotmaster

Conclusion

A robotic simulation and measurement platform were developed to enable RPL measurements of 2D or 3D complexly shaped RPL-coated objects such as a radiotherapy fixation mask. Next, RPL coating procedures will be evaluated and clinical beam plans will be investigated for post-treatment error detection in multi-fraction photon and hadron therapy.