A low budget synthesis apparatus for reproducible production of dosimetry gels

PO-1760

Abstract

A low budget synthesis apparatus for reproducible production of dosimetry gels

Authors: Armin Runz1,2, Ronald Eboue Teto1,3, Fabian Dinkel1,4, Wibke Johnen1,4, Alina Elter1,4,5, Stefan Dorsch1,4,5, Gernot Echner1,4, Christian P. Karger1,4

1German Cancer Research Center DKFZ, Medical Physics in Radiation Oncology, Heidelberg, Germany; 2National Center for Radiation Research in Oncology NCRO, Heidelberg Institute for Radiation Oncology HIRO , Heidelberg, Germany; 3National Center for Radiation Research in Oncology NCRO , Heidelberg Institute for Radiation Oncology HIRO , Heidelberg, Germany; 4National Center for Radiation Research in Oncology NCRO, Heidelberg Institute for Radiation Oncology HIRO, Heidelberg, Germany; 5University Hospital Heidelberg, Radiation Oncology, Heidelberg, Germany

Show Affiliations

Hide Affiliations

Purpose or Objective

To investigate the requirements for safety, accuracy and quality assurance in stereotactic irradiation of multiple brain metastases with a single isocenter, simple and highly reproducible production of polymer dosimetry gel (PAGAT) is required. The aim of this work was to develop a cost-effective system that allows producing the polymer gel in reproducible quality with simple handling.

Material and Methods

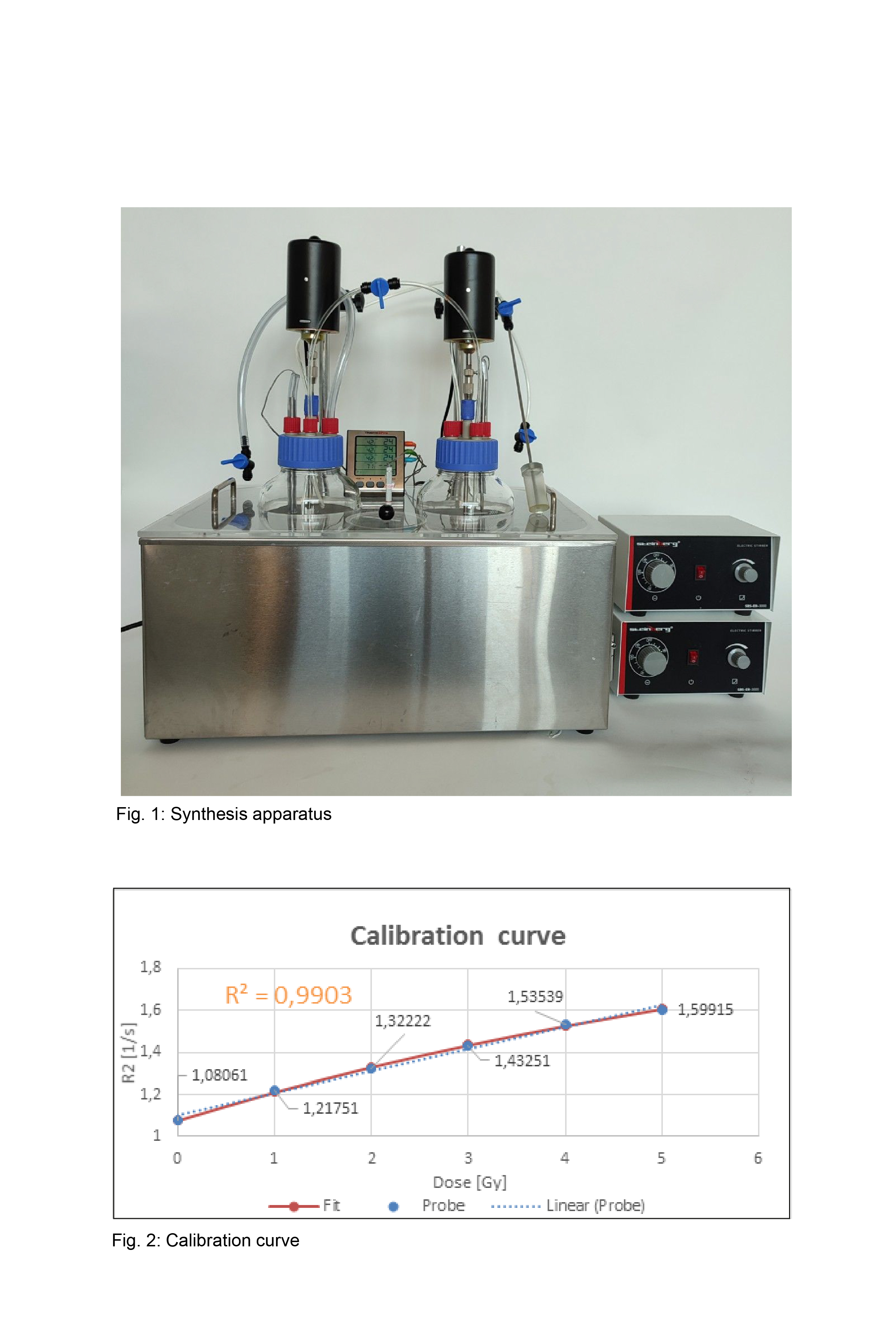

The production of PAGAT gel has been described in detail in Elter et. Al. [1]. The developed apparatus (Fig.1) consists of two reactors, in which anchor stirrers are installed that are suitable for mixing highly viscous media. A water bath originating from the gastronomy sector is used to heat the two reactors. A BBQ thermostat equipped with four thermocouples is used to control the temperature within 32° C and 42°C. The reactors are equipped with lids that have four access points through which connections for nitrogen supply, pressure control, insertion of temperature sensors and a connection of both reactors are feasible. The substrates to be mixed together later are prepared in the reactors. Reactor 1 contains the pork gelatin and reactor 2 the monomer solution of the two acrylamide substances. After preparation, the reactors are placed in the preheated water bath and closed with the lids. After the substrates have dissolved in both vessels, the acrylamide solution is transferred to the gelatin by means of negative pressure and mixed there for some time. After driving out the oxygen with nitrogen and then applying a negative pressure of 800mbar, a most of of the dissolved oxygen can be removed. The final PAGAT gel can then be transferred to the measurement containers to be irradiated using a tap.

Results

The described system can produce up to 1.5L PAGAT gel in reproducible quality and in a time of approx. 2.5 hours. The oxygen contamination can be considerably reduced by the closed system using nitrogen purging in combination with a negative pressure. The calibration curves (Fig.2) generated by irradiating the PAGAT gels were comparable to Elter et. al.. The cost of this system was approx. 1500€.

Conclusion

With the system, it is possible to further automate the polymer gel production by installing electronic valves together with an appropriate control technology.

[1] Elter et. al., Biomedical Physics & Engineering Express 7, 057001, 2021

Acknowledgement: This project was supported by the German Cancer Aid (grant no. 70114398).